Accurately Measure 3lpe Coating Thickness

Introducing our most advanced solution for ensuring the integrity and service life of steel pipes and fittings: the Advanced 3LPE Coating Thickness Measurement System. Designed to the latest industry standards, this innovative product is essential for accurately measuring the thickness of factory-applied three-layer extruded polyethylene coatings as well as one or more layers of sintered polyethylene coatings.

The 3LPE coating thickness measurement system is designed to provide accurate and reliable measurements, ensuring your steel pipes and fittings are adequately protected against corrosion. Not only does the system improve the durability of your infrastructure, it also helps maintain compliance with industry standards, ultimately saving you time and resources.

Our commitment to quality and innovation is reflected in every aspect of our operations. By combining advanced measurement technology with our extensive experience in coating applications, we help our customers make informed decisions about their corrosion protection strategies.

Product Specification

Company Advantage

In summary, our expertise in 3LPE coating applications and commitment to quality assurance make us a trusted partner in the industry. By accurately measuring coating thickness, we ensure that our products not only meet but exceed our customers’ expectations, protecting their investment for many years to come.

Product advantage

One of the main benefits of accurately measuring 3LPE coating thickness is quality control. By adhering to the specified requirements for factory-applied coatings, manufacturers can guarantee that their products meet industry standards, thereby reducing the risk of corrosion and extending the service life of the pipeline. This is especially important for a company like ours, located in Cangzhou, Hebei Province, which has been producing high-quality coatings since 1993. With a large 350,000 square meter factory and 680 employees, we prioritize precision in our manufacturing processes.

Product Shortcoming

One significant challenge is that measurements can be inaccurate due to environmental factors or equipment limitations. Inconsistent readings can result in over- or under-coating, compromising the protective qualities of the 3LPE layer. Additionally, the complexity of multi-layer sintered polyethylene coatings can further complicate the measurement process, requiring advanced techniques and equipment.

FAQ

Q1:What is 3LPE coating?

3LPE coating consists of a factory-applied three-layer system consisting of a fusion-bonded epoxy layer, a polyethylene adhesive layer, and a polyethylene outer layer. This combination provides excellent corrosion resistance, making it an ideal choice for steel pipe and fittings used in a variety of industries.

Q2:Why is coating thickness important?

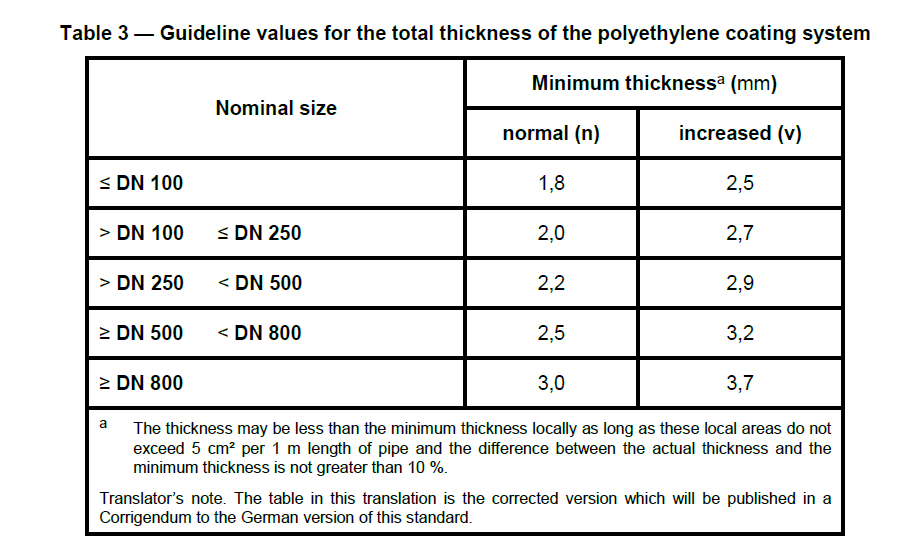

The thickness of 3LPE coatings is critical to ensure optimal corrosion protection. Insufficient thickness can lead to premature failure, while excessive thickness can lead to application difficulties and increased costs. Therefore, accurate measurement is essential.

Q3: How to measure coating thickness?

There are several methods for measuring 3LPE coating thickness, including magnetic induction, ultrasonic testing, and destructive testing. Each method has its advantages and is suitable for different applications. It is important to choose the right method based on the specific requirements of the project.

Q4:Where can I buy quality 3LPE coating products?

Located in Cangzhou, Hebei Province, our company has been a leader in the manufacture of high-quality 3LPE coated steel pipes and fittings since 1993. With a massive 350,000 square meter facility and a dedicated workforce of 680, we are committed to delivering products that meet the highest industry standards.