Advanced Natural Pipe Line Gas System

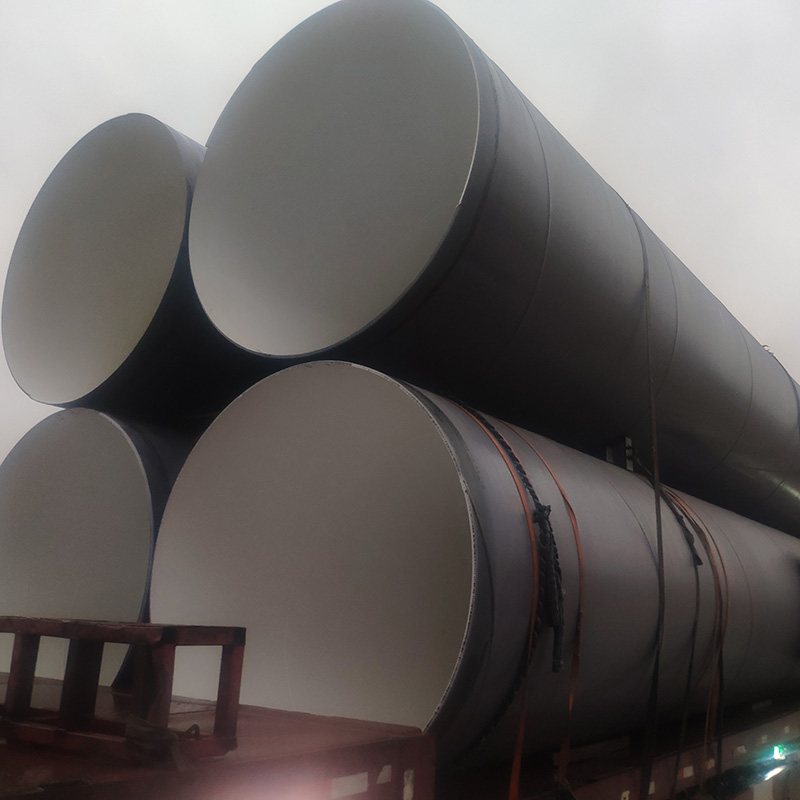

Introducing Advanced Gas Pipe Systems, a cutting-edge solution designed to meet the growing demands of the energy industry. Our large-diameter welded pipes play an important role in pipeline gas infrastructure construction, ensuring the safe and efficient transportation of natural gas, oil and other fluids over long distances.

Advanced pipe line gas systems are designed with durability and reliability in mind. Our large-diameter welded pipes are manufactured using advanced technology to ensure strength and longevity, making them ideal for the rigorous demands of pipeline construction. Whether you are transporting natural gas, oil, or other fluids, our pipes provide the performance and safety you need.

As the energy industry continues to evolve, our commitment to innovation and quality remains steadfast. We understand the critical role pipeline infrastructure plays in powering economies and communities, and we are proud to contribute to this important industry.

Product Specification

| Standardization Code | API | ASTM | BS | DIN | GB/T | JIS | ISO | YB | SY/T | SNV |

|

Serial Number of Standard |

A53 |

1387 |

1626 |

3091 |

3442 |

599 |

4028 |

5037 |

OS-F101 | |

| 5L | A120 |

102019 |

9711 PSL1 |

3444 |

3181.1 |

5040 |

||||

| A135 | 9711 PSL2 |

3452 |

3183.2 |

|||||||

| A252 |

14291 |

3454 |

||||||||

| A500 |

13793 |

3466 |

||||||||

| A589 |

Main feature

1.High durability.

2.Corrosion Resistance.

3.Ability to withstand extreme pressure.

Product Advantage

1. First, it ensures efficient transportation of natural gas, greatly reducing energy losses during transportation.

2. Large-diameter welded pipes facilitate increased flow rates, thus meeting the growing energy needs of cities and industrial areas.

3.These pipes are designed to withstand high pressures and extreme environmental conditions, ensuring safety and reliability.

Product shortcoming

1. The initial investment in building such infrastructure can be large, often requiring significant capital and resources.

2. Maintenance of large-diameter pipeline can be challenging, as any leaks or damage can result in expensive repairs and environmental harm.

3. Regulatory compliance and environmental issues can complicate the development and expansion of pipeline networks.

FAQ

Q1. What is a large diameter welded pipe?

Large diameter welded pipes are sturdy pipes used in the construction of natural gas pipeline infrastructure. Their strength and durability make them ideal for transporting natural gas and other fluids over long distances.

Q2. Why are these pipelines so important to the energy industry?

These pipelines are essential for transporting energy efficiently and safely. They minimize the risk of leaks and ensure that natural gas reliably reaches consumers.

Q3. How does your company ensure the quality of its products?

Our company adheres to strict quality control measures throughout the entire production process. We utilize advanced technology and skilled personnel to produce pipes that meet international standards.

Q4. What is the future of the pipeline natural gas system?

As energy demand continues to grow, developing advanced pipeline systems will be critical. Innovations in materials and technology will improve the efficiency and safety of natural gas transportation.