High Quality For Spiral Welded Carbon Steel Pipe – ASTM A234 WPB & WPC pipe fittings including elbows, tee, reducers – Spiral

High Quality For Spiral Welded Carbon Steel Pipe – ASTM A234 WPB & WPC pipe fittings including elbows, tee, reducers – Spiral Detail:

Chemical Composition of ASTM A234 WPB & WPC

|

Element |

Content, % |

|

|

ASTM A234 WPB |

ASTM A234 WPC |

|

|

Carbon [C] |

≤0.30 |

≤0.35 |

|

Manganese [Mn] |

0.29-1.06 |

0.29-1.06 |

|

Phosphorus [P] |

≤0.050 |

≤0.050 |

|

Sulfur [S] |

≤0.058 |

≤0.058 |

|

Silicon [Si] |

≥0.10 |

≥0.10 |

|

Chromium [Cr] |

≤0.40 |

≤0.40 |

|

Molybdenum [Mo] |

≤0.15 |

≤0.15 |

|

Nickel [Ni] |

≤0.40 |

≤0.40 |

|

Copper [Cu] |

≤0.40 |

≤0.40 |

|

Vanadium [V] |

≤0.08 |

≤0.08 |

*The Carbon Equivalent [C.E.=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15] shall be no greater than 0.50 and shall be reported on MTC.

Mechanical Properties of ASTM A234 WPB & WPC

|

ASTM A234 Grades |

Tensile Strength, min. |

Yield Strength, min. |

Elongation %, min |

|||

|

ksi |

MPa |

ksi |

MPa |

Longitudinal |

Transverse |

|

|

WPB |

60 |

415 |

35 |

240 |

22 |

14 |

|

WPC |

70 |

485 |

40 |

275 |

22 |

14 |

*1. WPB and WPC pipe fittings manufactured from plates shall have a minimum elongation of 17%.

*2. Unless required, hardness value doesn’t need to be reported.

Manufacture

The ASTM A234 carbon steel pipe fittings may be made from seamless pipes, welded pipes or plates by shaping operations of pressing, piercing, extruding, bending, fusion welding, machining, or by a combination of two or more these operations. All welds including welds in tubular products from which fittings are made shall be made in accordance with ASME Section IX. Post-weld heat treatment at 1100 to 1250°F[595 to 675°C] and radiographic examination shall be performed after the welding process.

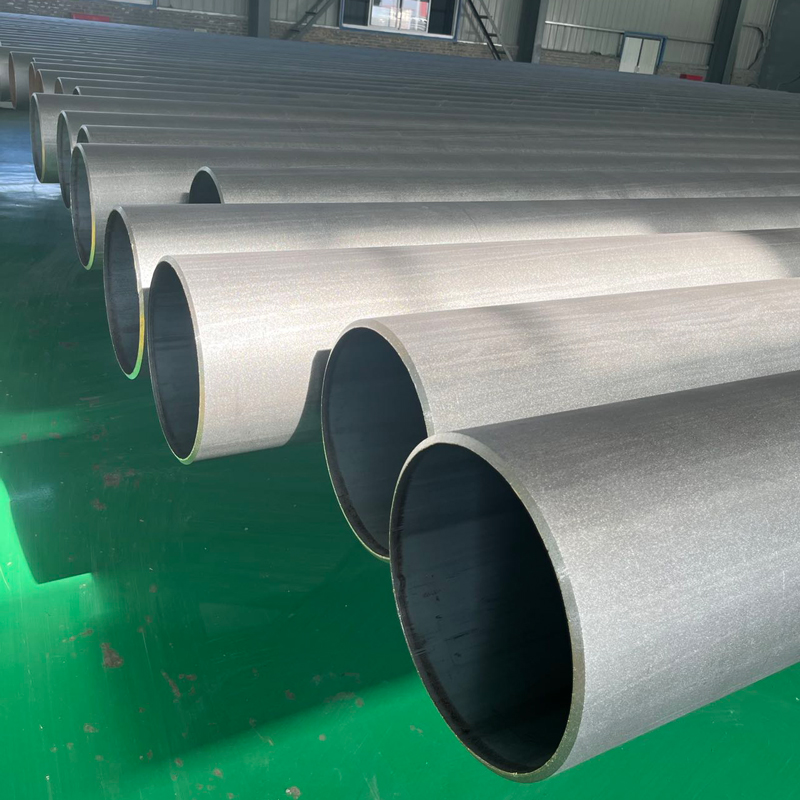

Product detail pictures:

Related Product Guide:

abide by the contract, conforms on the market requirement, joins from the market competition by its good quality likewise as provides more comprehensive and superb support for customers to let them become large winner. The pursue of the company, is definitely the clients' pleasure for High Quality For Spiral Welded Carbon Steel Pipe – ASTM A234 WPB & WPC pipe fittings including elbows, tee, reducers – Spiral , The product will supply to all over the world, such as: Los Angeles, Lesotho, Bulgaria, Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services for you. We warmly welcome you to contact us and please feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specifications or inquiries today.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.