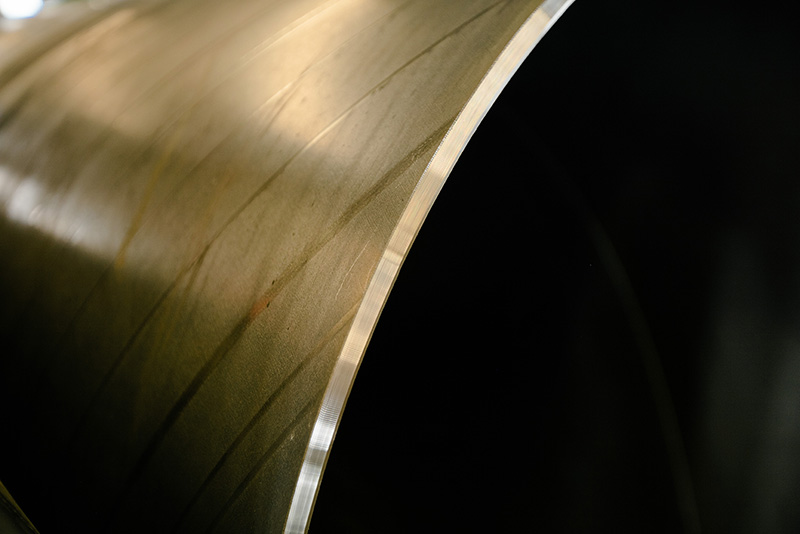

High Quality Spiral Submerged Arc Pipe Efficient Fluid Transportation

Introducing our high quality spiral submerged arc pipes, designed for efficient fluid transport and engineered to the strict standards set by European regulations. Our products are manufactured from cold formed welded structural hollow sections and are available in round, square or rectangular shapes. This ensures that our pipes not only meet but exceed the technical delivery conditions specified for structural hollow sections, providing you with a reliable fluid transport solution.

Our factory is located in the heart of Cangzhou, Hebei Province and has been a leader in the industry since its establishment in 1993. The factory covers an area of 350,000 square meters and is equipped with state-of-the-art technology and machinery, allowing us to produce high-quality pipes that are both durable and efficient. With total assets of RMB 680 million and 680 dedicated employees, we are committed to maintaining the highest standards of quality and service.

Our spiral submerged arc pipe are engineered for performance and ensure efficient and safe fluid transport. The cold-formed design requires no subsequent heat treatment, making our pipes not only cost-effective but also environmentally friendly. Whether you are in construction, oil and gas, or any industry that requires reliable fluid transport, our pipes are the perfect choice.

Product Specification

Mechanical Property

|

steel grade |

minimum yield strength |

Tensile strength |

Minimum elongation |

Minimum impact energy |

||||

|

Specified thickness |

Specified thickness |

Specified thickness |

at test temperature of |

|||||

|

<16 |

>16≤40 |

<3 |

≥3≤40 |

≤40 |

-20℃ |

0℃ |

20℃ |

|

| S235JRH |

235 |

225 |

360-510 |

360-510 |

24 |

- |

- |

27 |

| S275J0H |

275 |

265 |

430-580 |

410-560 |

20 |

- |

27 |

- |

| S275J2H |

27 |

- |

- |

|||||

| S355J0H |

365 |

345 |

510-680 |

470-630 |

20 |

- |

27 |

- |

| S355J2H |

27 |

- |

- |

|||||

| S355K2H |

40 |

- |

- |

|||||

Product advantage

One of the main advantages of high-quality spiral submerged arc tubes is their excellent strength and durability. The cold forming process enhances the structural integrity of the material, making it suitable for a variety of demanding applications, including construction and infrastructure projects. Additionally, spiral welding technology allows for longer pipes to be produced, reducing the need for joints and minimizing potential weak points.

Another significant benefit is that these pipes are cost-effective. The manufacturing process is efficient, which can reduce production costs. This efficiency, combined with the high quality of the final product, makes spiral submerged arc tubes an attractive choice for many businesses.

Product Shortcoming

One potential disadvantage is the limited availability of sizes and specifications compared to other types of pipe. While the cold forming process offers many advantages, it may not be suitable for all applications, especially those requiring specific heat treatments or unique dimensions.

In addition, although the manufacturing plant in Cangzhou City, Hebei Province has strong production capabilities and 680 skilled employees, reliance on a single factory may pose supply chain risks. Companies must ensure that contingency plans are in place to mitigate any disruptions.

FAQS

Q1:What is a high quality spiral submerged arc tube?

High-quality spiral submerged arc pipe is a welded structural hollow section that is cold formed and does not require subsequent heat treatment. The product is available in a variety of shapes, including round, square and rectangular, allowing flexibility for different uses. European standards define the technical delivery conditions of these pipes, ensuring that they meet strict quality and performance standards.

Q2: Where is this product manufactured?

Our factory has been producing high quality spiral submerged arc welded pipes in Cangzhou, Hebei Province since 1993. The factory covers an area of 350,000 square meters, has total assets of RMB 680 million and employs approximately 680 skilled workers. This extensive infrastructure enables us to maintain high production standards and meet the growing demands of the market.

Q3:Why choose high quality spiral submerged arc tube?

Choosing high-quality spiral submerged arc pipe means choosing reliability and strength. The cold forming process enhances the structural integrity of the pipe, making it suitable for a variety of applications, including the construction, infrastructure and energy sectors. Our commitment to quality ensures that every pipe produced meets the highest standards, giving engineers and contractors peace of mind.