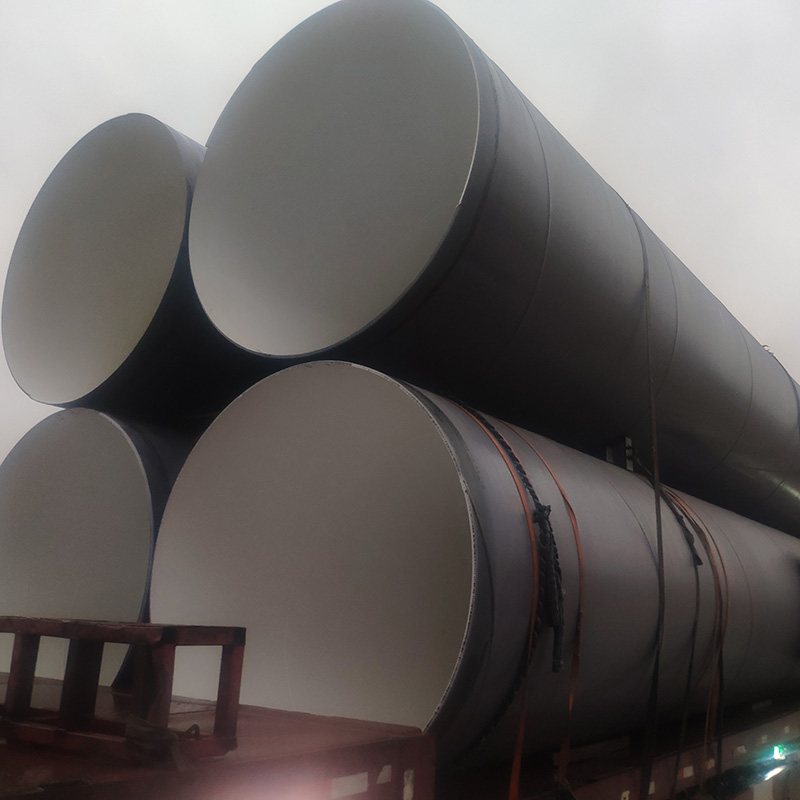

Large Diameter Welded Pipes In Pipeline Gas Infrastructure

One of the main reasons Large diameter welded pipes are widely used in piped gas infrastructure is their ability to withstand high-pressure environments. The transportation of natural gas and other fluids requires pipelines that can withstand the enormous pressures created during the process. Large diameter welded pipe is designed to handle these pressures without compromising its structural integrity, making it ideal for piped gas systems.

| Standardization Code | API | ASTM | BS | DIN | GB/T | JIS | ISO | YB | SY/T | SNV |

|

Serial Number of Standard |

A53 |

1387 |

1626 |

3091 |

3442 |

599 |

4028 |

5037 |

OS-F101 | |

| 5L | A120 |

102019 |

9711 PSL1 |

3444 |

3181.1 |

5040 |

||||

| A135 | 9711 PSL2 |

3452 |

3183.2 |

|||||||

| A252 |

14291 |

3454 |

||||||||

| A500 |

13793 |

3466 |

||||||||

| A589 |

In addition to its ability to withstand high pressures, large diameter welded pipe is known for its durability and longevity. These pipes are made of high-quality materials and advanced welding technology, ensuring their reliability and long service life. As a result, pipeline natural gas operators can rely on these pipelines to safely and efficiently transport natural gas and other fluids over the long term.

Another advantage of Large diameter welded pipe in pipe line gas infrastructure is its cost-effectiveness. Due to their durability and long service life, these pipelines require minimal maintenance and replacement, thus reducing operating costs for pipeline natural gas operators. Additionally, using Large diameter welded pipe to efficiently transport natural gas and other fluids helps reduce energy waste and maximize the overall efficiency of pipe line gas systems.

Additionally, large diameter welded pipe offers flexibility in design and construction, making it suitable for a variety of pipeline natural gas applications. These pipes can be customized to meet specific project requirements, allowing pipe line gas systems to be constructed in challenging terrain and environments. Whether it is a long-distance pipeline or a cross-border natural gas transmission system, large diameter welded pipe provides the versatility needed to adapt to different project needs.

The use of Large diameter welded pipe in pipeline natural gas infrastructure also contributes to environmental sustainability. By enabling efficient movement of natural gas and other fluids, these pipelines help reduce carbon emissions and minimize the environmental impact of energy transportation. Additionally, the durability and longevity of large diameter welded pipe helps reduce the need for frequent replacement and repairs, thereby contributing to the overall sustainability of the pipe line gas system.

In summary, Large diameter welded pipes are crucial to the construction of pipeline gas infrastructure. Their ability to withstand high pressures, durability, cost-effectiveness, flexibility and environmental sustainability make them the first choice for pipeline natural gas applications. As demand for natural gas and other fluids continues to grow, large diameter welded pipe will play an increasingly important role in supporting the energy industry and meeting consumer demand.