Introduce:

In the pipeline segment, the two main players, seamless and welded, have been vying for supremacy. While both function similarly, they have unique characteristics that make them suitable for specific applications. In this blog, we delve into the nuances of seamless pipe vs welded pipe, explore their differences and applications, and ultimately help you understand which type is best for your needs.

Seamless pipe:

Seamless pipe, as the name suggests, is manufactured without any welded joints or seams. They are made by extruding a solid cylindrical billet through a perforated rod to form a hollow tube. This manufacturing process ensures uniformity and consistency in the pipe structure, allowing it to withstand higher pressures and temperatures.

Advantages of seamless pipes:

1. Strength and Reliability: Seamless tubing has exceptional strength and reliability due to its internal pressure rating and no welded joints. This quality makes them ideal for applications requiring a high level of durability, such as oil and gas transportation and refining processes.

2. Aesthetics: Seamless tubing is known for its smooth, polished appearance, making it a popular choice for architectural structures, auto parts, and high-end furniture.

3. Corrosion resistance: Seamless pipes generally exhibit excellent corrosion resistance, especially when made of materials such as stainless steel or alloy mixtures. This characteristic is advantageous for applications involving exposure to corrosive substances or harsh environments.

Welded pipe:

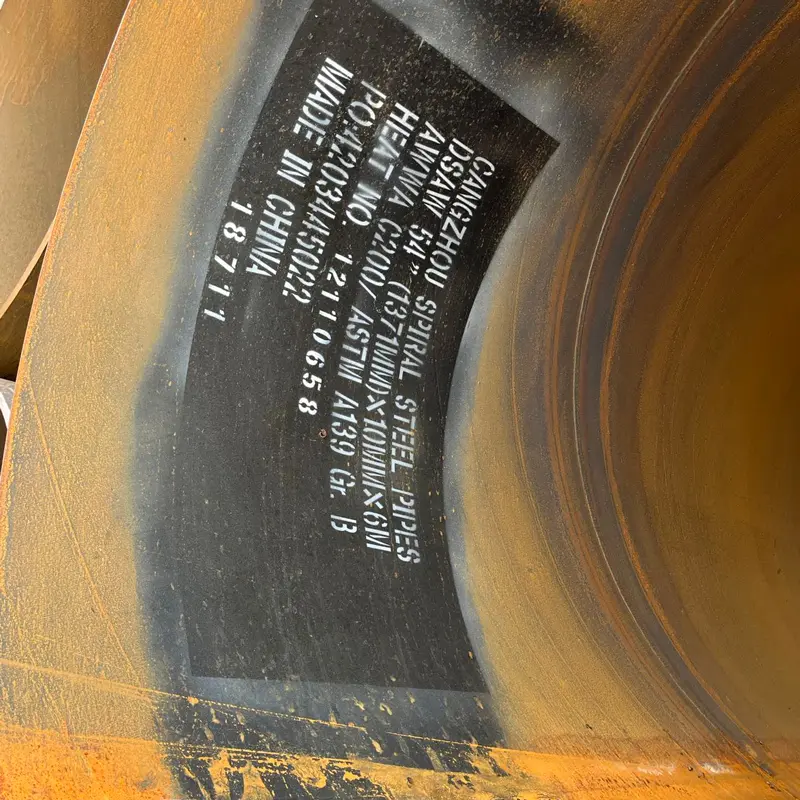

In contrast to seamless pipe, welded pipe is formed by rolling a flat steel strip into a cylindrical shape through a series of rollers. The edges of the strip are then bonded together by various welding techniques such as electric resistance welding (ERW), longitudinal submerged arc welding (LSAW) or helical submerged arc welding (HSAW). The welding process gives these pipes different characteristics and qualities.

Advantages of welded pipes:

1. Cost-effectiveness: Welded pipes are generally more cost-effective than seamless pipes, mainly due to the efficiency and speed of the manufacturing process. As such, they are often favored in applications where cost-efficiency is critical, such as piping, structural framing, and low-pressure fluid transportation.

2. Versatility: Welded pipes have greater versatility in size and shape as they can be manufactured in a variety of diameters, lengths and thicknesses. This adaptability makes them suitable for a wide range of applications from small piping systems to large industrial infrastructures.

3. Improved welding quality: The welding process used to join the edges of the pipes enhances the strength of the seam, ensuring reliable performance even under moderate pressure. This characteristic makes welded pipe suitable for applications involving fluid transfer, construction, and plumbing within buildings.

In conclusion:

So, which type of plumbing should you choose? The answer lies in understanding the specific requirements of your project or application. Seamless tubing excels in high-pressure and high-temperature environments, while welded tubing is cost-effective and versatile. Make an informed decision by considering factors such as strength, durability, cost, and application needs.

Remember, seamless pipe is the epitome of strength and reliability, ideal for critical applications, while welded pipe offers cost-effective solutions and adaptability. Ultimately, an industry expert or professional must be consulted to determine the option that best suits your specific needs and ensures a successful and efficient outcome for your project.

Post time: Aug-25-2023