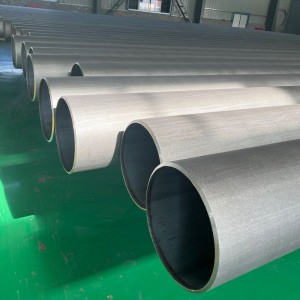

S235 J0 Spiral Steel Pipe – Excellent Performance Of Large Diameter Welded Pipe

We are proud to introduce our top-of-the-line product, S235 J0 Spiral Steel Pipe, designed to meet the growing needs of various industries. As a leading manufacturer in the field, we utilize advanced technology and expertise to manufacture high-quality line pipe with exceptional durability and performance.

Our spiral steel pipes are made from strip steel coils through automated double-wire double-sided submerged arc welding process. Through constant temperature extrusion molding technology, we ensure that each tube is produced with the highest precision and consistency. This meticulous manufacturing process ensures that our products meet the highest quality standards, making them ideal for a variety of applications.

Mechanical Property

|

steel grade |

minimum yield strength |

Tensile strength |

Minimum elongation |

Minimum impact energy |

||||

|

Specified thickness |

Specified thickness |

Specified thickness |

at test temperature of |

|||||

|

<16 |

>16≤40 |

<3 |

≥3≤40 |

≤40 |

-20℃ |

0℃ |

20℃ |

|

| S235JRH |

235 |

225 |

360-510 |

360-510 |

24 |

- |

- |

27 |

| S275J0H |

275 |

265 |

430-580 |

410-560 |

20 |

- |

27 |

- |

| S275J2H |

27 |

- |

- |

|||||

| S355J0H |

365 |

345 |

510-680 |

470-630 |

20 |

- |

27 |

- |

| S355J2H |

27 |

- |

- |

|||||

| S355K2H |

40 |

- |

- |

|||||

Our spiral steel pipes are made from strip steel coils through automated double-wire double-sided submerged arc welding process. Through constant temperature extrusion molding technology, we ensure that each tube is produced with the highest precision and consistency. This meticulous manufacturing process ensures that our products meet the highest quality standards, making them ideal for a variety of applications.

Compared with traditional welded pipes, S235 J0 spiral steel pipe has the following significant features:

A. During the forming process, the steel plate deforms evenly and has minimal residual stress. Not only does this extend the life of the pipe, it also ensures that the pipe surface is smooth and free of scratches or defects.

b. Our advanced double-sided submerged arc welding process enables precise welding in the best position. This significantly reduces the occurrence of defects such as misaligned edges, welding deviations, and incomplete welding. As a result, our pipes have excellent welding quality, are easy to control and ensure excellent performance.

C. Quality is our top priority. Therefore, we perform thorough 100% quality inspection on every steel pipe we produce. This comprehensive inspection guarantees that our pipes meet the highest industry standards, giving you peace of mind throughout the production and use process.

At Cangzhou Spiral Steel Pipe Group Co., Ltd., we are very proud of manufacturing S235 J0 Spiral Steel Pipe. We are located in Cangzhou City, Hebei Province and have been serving the industry since 1993. Covering an area of 350,000 square meters and total assets of 680 million yuan, it has laid a solid foundation for excellent production capabilities. Our dedicated team of 680 skilled employees work tirelessly to ensure seamless production and timely delivery of 400,000 tons of spiral steel pipes annually.

Chemical Composition

|

Steel grade |

Type of de-oxidation a |

% by mass, maximum |

||||||

|

Steel name |

Steel number |

C |

C |

Si |

Mn |

P |

S |

Nb |

|

S235JRH |

1.0039 |

FF |

0,17 |

— |

1,40 |

0,040 |

0,040 |

0.009 |

|

S275J0H |

1.0149 |

FF |

0,20 |

— |

1,50 |

0,035 |

0,035 |

0,009 |

|

S275J2H |

1.0138 |

FF |

0,20 |

— |

1,50 |

0,030 |

0,030 |

— |

|

S355J0H |

1.0547 |

FF |

0,22 |

0,55 |

1,60 |

0,035 |

0,035 |

0,009 |

|

S355J2H |

1.0576 |

FF |

0,22 |

0,55 |

1,60 |

0,030 |

0,030 |

— |

|

S355K2H |

1.0512 |

FF |

0,22 |

0,55 |

1,60 |

0,030 |

0,030 |

— |

|

a. The deoxidation method is designated as follows: FF: Fully killed steel containing nitrogen binding elements in amounts sufficient to bind available nitrogen (e.g. min. 0,020 % total Al or 0,015 % soluble Al). b. The maximum value for nitrogen does not apply if the chemical composition shows a minimum total Al content of 0,020 % with a minimum Al/N ratio of 2:1, or if sufficient other N-binding elements are present. The N-binding elements shall be recorded in the Inspection Document. |

||||||||

At Cangzhou Spiral Steel Pipe Group Co., Ltd., we are very proud of manufacturing S235 J0 Spiral Steel Pipe. We are located in Cangzhou City, Hebei Province and have been serving the industry since 1993. Covering an area of 350,000 square meters and total assets of 680 million yuan, it has laid a solid foundation for excellent production capabilities. Our dedicated team of 680 skilled employees work tirelessly to ensure seamless production and timely delivery of 400,000 tons of spiral steel pipes annually.

In summary, S235 J0 spiral steel pipe provides unmatched quality and durability for your large diameter welded pipe needs. With their advanced manufacturing processes, superior welding quality and thorough quality inspections, our products are guaranteed to exceed your expectations. Trust Cangzhou Spiral Steel Pipe Group Co., Ltd.’s expertise and experience to meet all your steel pipe needs.