Seamless Carbon Steel Pipes ASTM A106 Gr.B

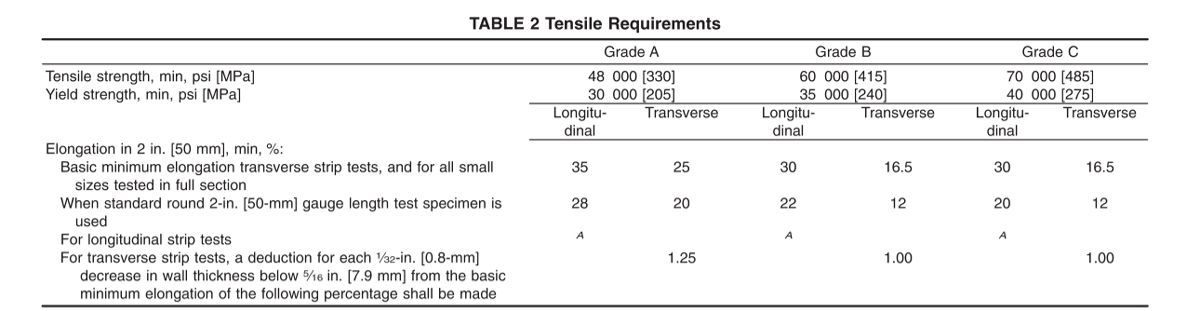

Mechanical property of the A106 seamless pipes

Chemical position of the A106 pipes

Heat treatment

Hot-finished pipe need not be heat treated. When hot-finished pipes is heat treated, it shall be treated at a temperature of 650℃ or higher.

Bending test required.

Flattening test is not required.

Hydrostatic test is not mandatory.

As an alternative to the hydrostatic test at the option of the manufacturer or where specified in the PO, it shall be permissible for the full body of each pipe to be tested with a nondestructive electric test.

Nondestructive Electric Test

As an alternative to the hydrostatic test at the option of the manufacturer or where specified in the PO as an alternative or addition to the hydrostatic test, the full body of each pipe shall be tested with a nondestructive electric test in accordance with Practice E213, E309 or E570. In such cases, the marking of each length of pipes shall include the letters NDE.

The minimum wall thickness at any point shall not be more than 12.5% under the specified wall thickness.

Lengths: if definite lengths are not required, pipe may be ordered in single random lengths or in double random lengths meeting the following requirements:

single random lengths shall be 4.8m to 6.7 m

double random lengths shall have a minimum average length of 10.7m and shall have a minimum length of 6.7m