Strength and Reliability of Hollow-Section Structural Pipes: An In-Depth Look at Spiral Submerged Arc Welded Pipe and API 5L Line Pipe

Introduce:

In the world of construction and infrastructure development, choosing the right materials is crucial. Hollow section structural pipes play a vital role in providing strength, durability and reliability to a variety of projects. In this blog, we will explore the characteristics and benefits of two important types of structural pipe: spiral submerged arc welded pipe and API 5L line pipe.

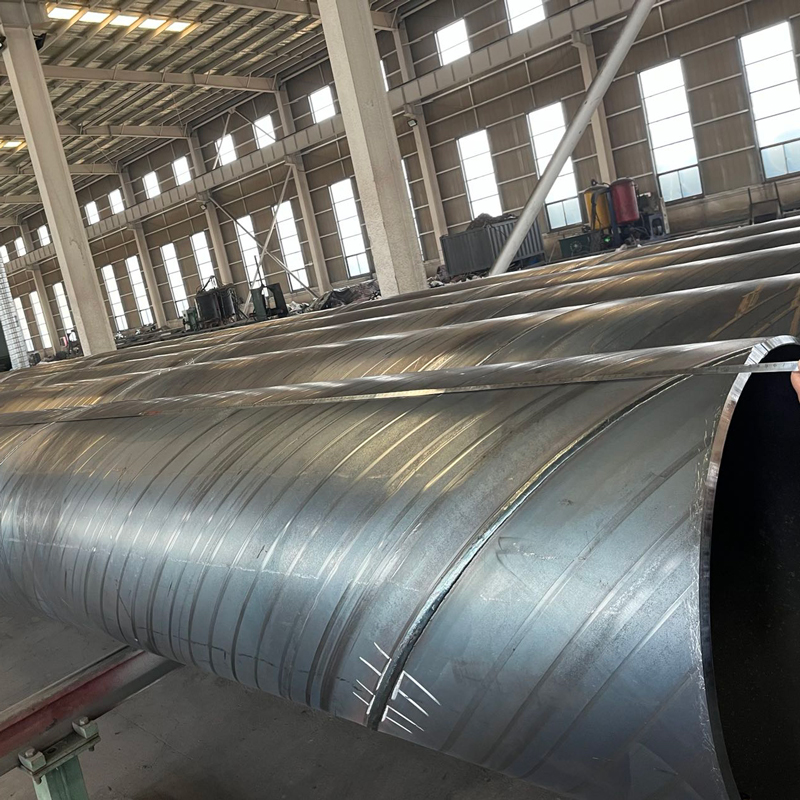

Spiral submerged arc welded pipe:

Submerged arc welded (SAW) pipe, also known as SSAW pipe, is used in a wide range of applications. The unique feature of SSAW pipe is its spiral seams, which provide greater strength and load-bearing capacity compared to other types of pipe. This unique design helps distribute stress evenly throughout the pipe, making it ideal for projects requiring structural integrity.

The Mechanical Properties of the SSAW pipe

|

steel grade |

minimum yield strength |

minimum Tensile strength |

Minimum Elongation |

|

B |

245 |

415 |

23 |

|

X42 |

290 |

415 |

23 |

|

X46 |

320 |

435 |

22 |

|

X52 |

360 |

460 |

21 |

|

X56 |

390 |

490 |

19 |

|

X60 |

415 |

520 |

18 |

|

X65 |

450 |

535 |

18 |

|

X70 |

485 |

570 |

17 |

The Chemical composition of the SSAW pipes

|

steel grade |

C |

Mn |

P |

S |

V+Nb+Ti |

|

Max % |

Max % |

Max % |

Max % |

Max % |

|

|

B |

0.26 |

1.2 |

0.03 |

0.03 |

0.15 |

|

X42 |

0.26 |

1.3 |

0.03 |

0.03 |

0.15 |

|

X46 |

0.26 |

1.4 |

0.03 |

0.03 |

0.15 |

|

X52 |

0.26 |

1.4 |

0.03 |

0.03 |

0.15 |

|

X56 |

0.26 |

1.4 |

0.03 |

0.03 |

0.15 |

|

X60 |

0.26 |

1.4 |

0.03 |

0.03 |

0.15 |

|

X65 |

0.26 |

1.45 |

0.03 |

0.03 |

0.15 |

|

X70 |

0.26 |

1.65 |

0.03 |

0.03 |

0.15 |

The Geometric tolerance of the SSAW pipes

|

Geometric tolerances |

||||||||||

|

outside diameter |

Wall thickness |

straightness |

out-of-roundness |

mass |

Maximum weld bead height |

|||||

|

D |

T |

|||||||||

|

≤1422mm |

>1422mm |

<15mm |

≥15mm |

pipe end 1.5m |

full length |

pipe body |

pipe end |

T≤13mm |

T>13mm |

|

|

±0.5% |

as agreed |

±10% |

±1.5mm |

3.2mm |

0.2% L |

0.020D |

0.015D |

‘+10% |

3.5mm |

4.8mm |

Hydrostatic Test

The pipe shall withstand the hydrostatic test without leakage through the weld seam or the pipe body

Jointers need not be hydrostatically tested, providedthat the portions of pipe used in marking the jointers were successfully hydrostatically tested prior to the joining operation.

Traceablity:

For PSL 1 pipe, the manufacturer shall establish and follow documented procedures for maintaining:

The heat identity until each related chmical tests is performed and conformance with the specified requirements is shown

The test-unit identity until each related mechanical tests is performed and conformance with the specified requirements is shown

For PSL 2 pipe, the manufacturer shall establish and follow documented procedures for maintaining the heat identity and the test-unit identity for such pipe. Such procedures shall provide means for tracing any length of pipe to the proper test unit and the related chemical test results.

One of the main advantages of SSAW pipe is its manufacturing flexibility. These pipes can be produced in a variety of sizes, diameters and thicknesses and can be customized to meet the requirements of a specific project. In addition, spiral submerged arc welded pipes are usually made of high-quality steel, making them corrosion-resistant and ensuring a longer service life.

API 5L Line Pipe:

API 5L line pipe is a widely used hollow section structural pipe that meets American Petroleum Institute (API) standards. These pipelines are designed to transport fluids, such as oil and natural gas, over long distances. API 5L line pipe is known for its high strength, durability and resistance to extreme environmental conditions.

The manufacturing process of API 5L line pipe involves strict quality control measures to ensure its reliability. These pipes are made of carbon steel and have excellent mechanical properties. Strict adherence to API standards ensures that these pipes can withstand high pressures and temperature changes, making them suitable for critical applications in the oil and gas industry.

Combined advantages:

When spiral submerged arc welded pipe and API 5L line pipe are combined, they provide unparalleled structural integrity and reliability. The spiral seams of SSAW pipe combined with the strength and durability of API 5L line pipe create a strong structural support system.

In addition to their respective advantages, the compatibility of spiral submerged arc welded pipe and API 5L line pipe increases the efficiency of pipeline projects. The versatility of SSAW pipe allows easy interconnection with API 5L line pipe, ensuring seamless flow of fluids within the pipe network.

In conclusion:

Hollow section structural pipes are of great importance when building strong infrastructure. The combined use of SSAW pipe and API 5L line pipe provides a powerful solution that provides strength, durability and reliability for a variety of projects. Whether supporting the foundations of tall buildings or transporting critical fluids over long distances, these pipes play an integral role in ensuring the longevity and stability of our infrastructure. By leveraging the strength of spiral submerged arc welded pipe and the reliability of API 5L line pipe, engineers can build a solid foundation for a better tomorrow.